GWJ3500 Heavy-load Accumulation Conveyor

Category:

Power and Free Conveyor

Chat with us now for a quick response.

Chat with us now for a quick response.

Keyword:

GWJ3500 Heavy-load Accumulation Conveyor

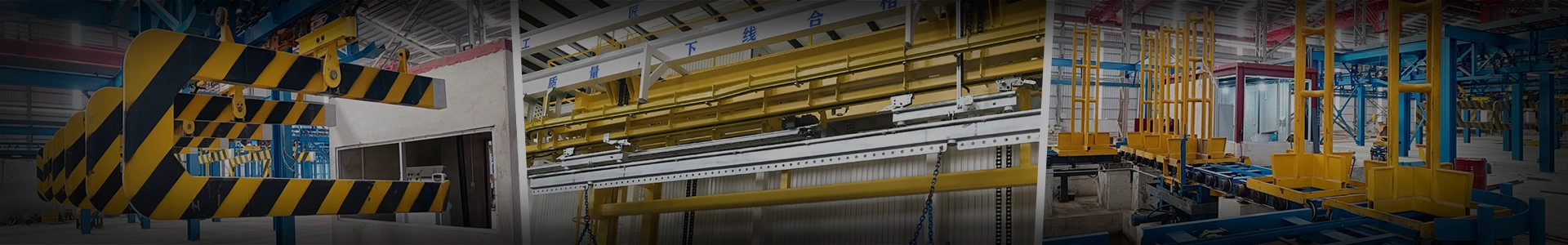

GWJ3500 accumulation type hanging conveyor is a new accumulation type hanging conveyor system developed by Chengde Guangda Conveyor Co., Ltd. It is a double-deck track three-dimensional space closed-loop continuous conveying system, suitable for complex process flows such as conveying, storage, branching, confluence, automatic loading and unloading of heavy and large finished goods with high degree of automation, multiple types of materials, and complex process, so that the factory production can be carried out in an orderly manner according to a certain process flow.

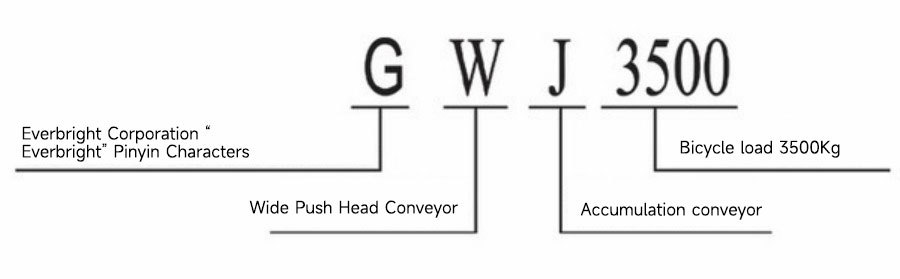

Model meaning

Technical parameters

Conveyor model: GWJ3500

Drag chain model: X-458

Nominal pitch (inch): 4

Actual pitch (mm): 102.4 Drag chain running speed (M/Min): ≤15

Ultimate tensile load (KN): 218 Track turning radius (minimum mm): 1000

Allowable tension (KN): 15 Traction track: Gong 10

Carrying capacity of single vehicle (Kg): 3500 Carrying track: Gong 12

System composition

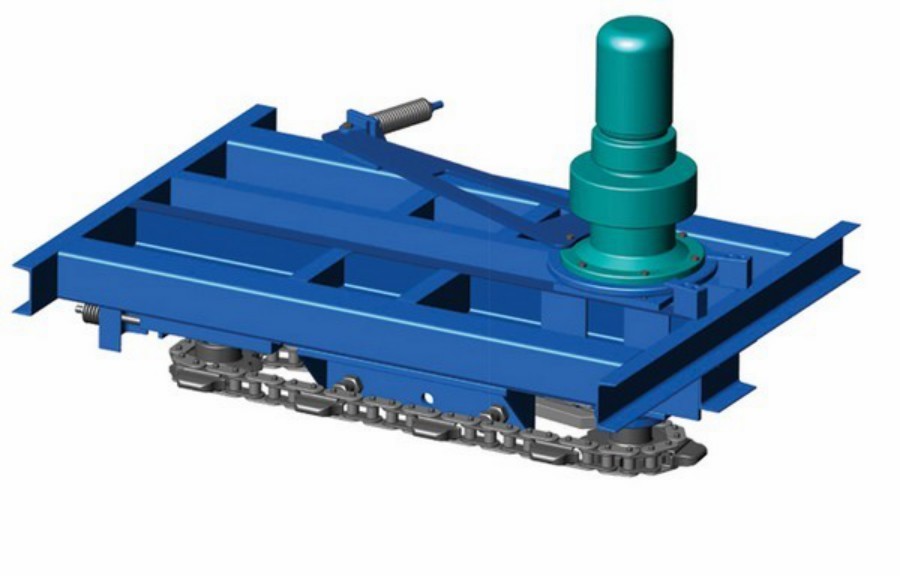

1. Drive device

The drive device of the accumulation and release suspension conveyor is set in the return chain section of the conveyor line and is the power source of the entire conveyor system. It consists of a frame, a special motor reducer, a drive chain, a driving master and slave gear system, an overload protection device, etc. It has mechanical overload protection and adopts a combination of large pitch meshing and standard pitch chain, which not only enhances the meshing accuracy, tooth root strength and service life of track teeth, but also reduces the pulsation speed during dragging, improves the "creeping" phenomenon during chain operation, and improves the service life of the track and the operating stability of the work.

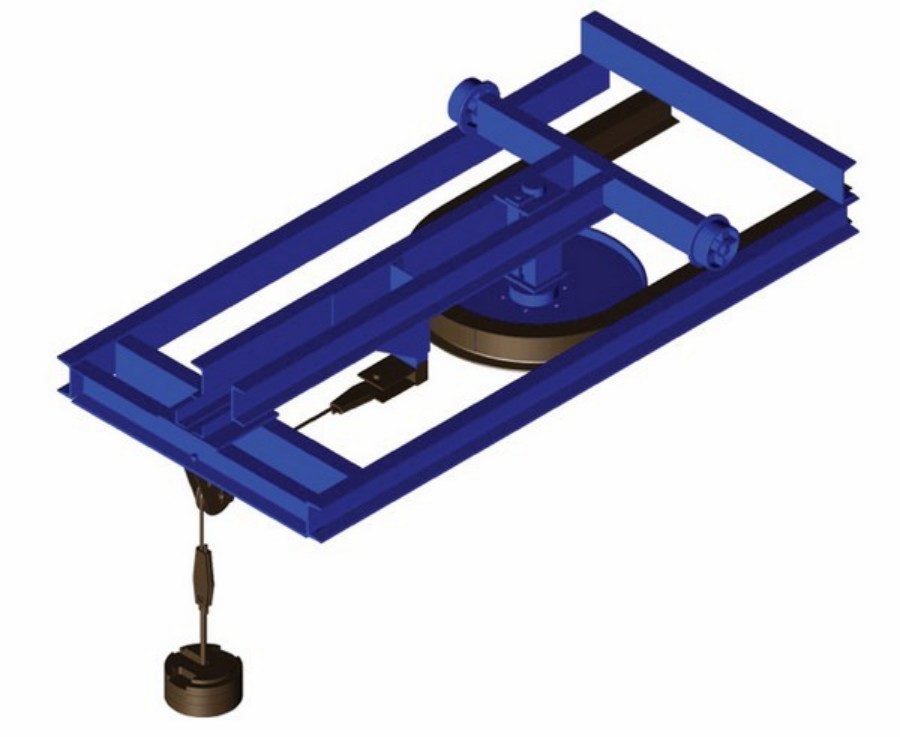

2. Tensioning device

2. Tensioning device

The tensioning device is arranged at the winding end of the drive device of the empty chain section of the conveyor line. There are two structural forms: heavy hammer type and pneumatic type. The characteristic of the heavy hammer tensioning device is that it has a large range of automatic compensation tensioning force.

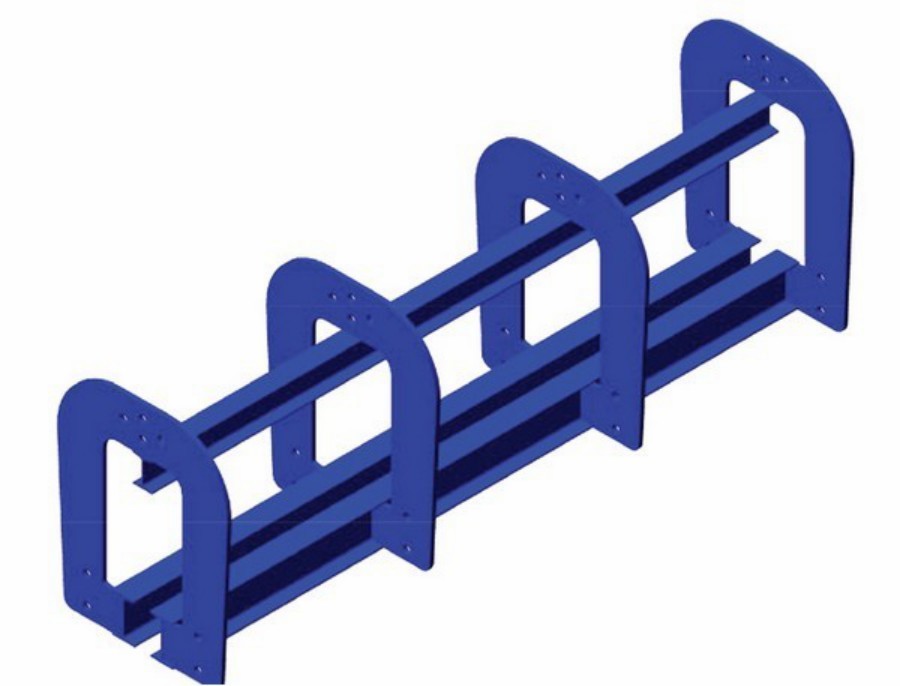

3. Tracks

3. Tracks

The accumulation track of this accumulation type suspension conveyor is a combined double-layer track. The upper traction track is a 10# I-beam track, and the lower bearing track is a double 12# I-beam track, which are connected into one by a bracket arranged at a certain interval. The bearing track adopts the double I-beam track form, which improves the bearing capacity and rigidity of the track.

4.Turnouts

There are two types of turnouts: basic turnouts and inspection turnouts. Basic turnouts are divided into two categories: branch turnouts and merging turnouts. There are eight types in total: straight left branch turnouts, straight right branch turnouts, curved left branch turnouts, curved right branch turnouts, straight left merging turnouts, straight right merging turnouts, curved left merging turnouts, curved right merging turnouts. Branch turnouts divide a line into two lines. Merging turnouts merge two lines into one line. According to the direction of the lead chain, each type of turnout can be divided into two types: straight and curved.

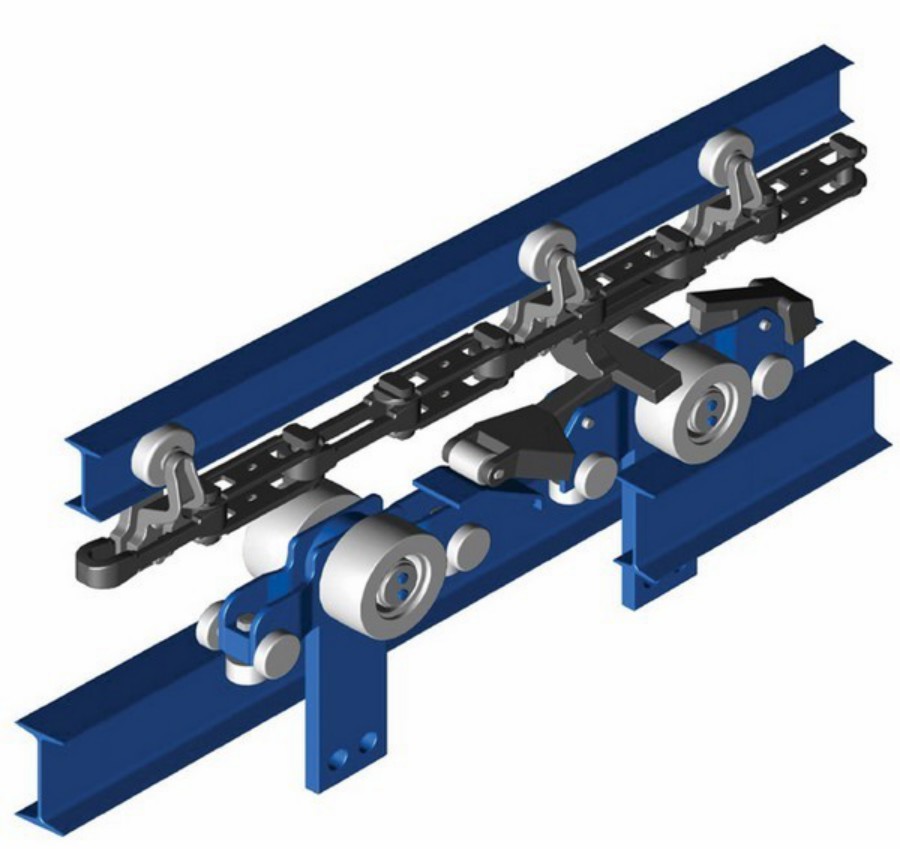

5.Chain

The lead components of this accumulation type suspension conveyor are composed of X-458 die-forged easy-to-remove chains, slides, and wide push heads.

6.Carrying trolley

This carrying trolley adopts a structure with a middle load wheel, balancing wheels and guide wheels on both sides, with less friction resistance in turning and better passing performance. The most commonly used carrying trolley of this accumulation type hanging conveyor is a two-type trolley group consisting of a front trolley, a rear trolley and a load beam. The trolley group has the functions of automatic accumulation and automatic release. The carrying trolley is also called an accumulation trolley or an accumulation trolley group. The front trolley of the carrying trolley is equipped with a rotatable lifting claw and a rotatable but non-reversible anti-escape claw. The lifting claw of this conveyor is a traditional lifting claw and a front shovel of the accumulation type conveyor made into one body, and a lifting roller is installed on the lifting claw, which has a simpler structure and more flexible action. It can also realize frictionless accumulation of the accumulation trolley, which is used to control the operation and stop of the trolley; the anti-escape claw is used to prevent the inertial escape of the trolley during movement and reliable engagement with the traction chain push rod when going downhill. The rear trolley of the load-carrying trolley is equipped with a wedge-shaped tail plate, and the lifting wheels of the lifting claws of the front trolley are lifted along the inclined surface of the tail plate to achieve intensive storage of the load-carrying trolleys. The connecting rod and load beam of the load-carrying trolley are non-standard components, and their length, size and structural type are determined during the line design.

Application

GET A FREE QUOTE