GX Series Light Conveyor

Category:

Light Duty Overhead Conveyor

Chat with us now for a quick response.

Chat with us now for a quick response.

Keyword:

GX Series Light Conveyor

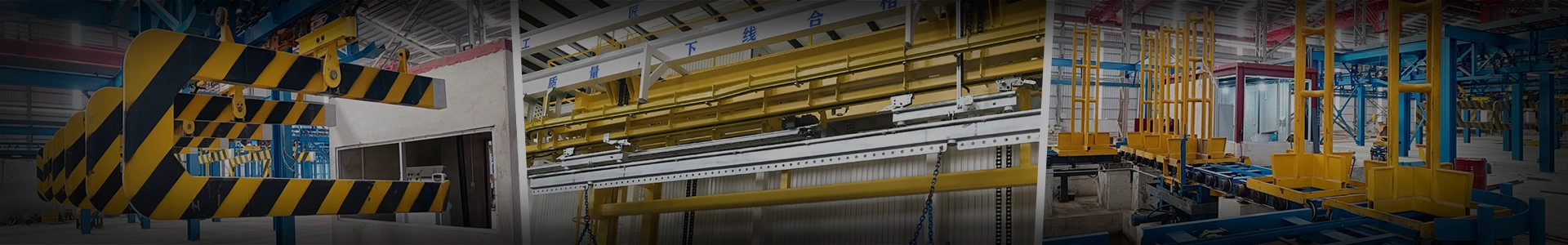

GX150/180/200/250/300/400 series light hanging conveyor is a high-end conveying equipment developed by Everbright Company based on market demand and combined with Everbright Company's many years of conveyor design and manufacturing technology and experience. It has the advantages of stable operation and accurate positioning of stepping operation.

Chain

This series of light conveyor chains are composed of chain plates, running wheels, guide wheels, intermediate sections and hangers. The chain plates are made of 40Cr steel, and the running wheels and guide wheels are all integral bearing wheels. The unique design can make the chain run smoothly, with low running resistance and high temperature resistance.

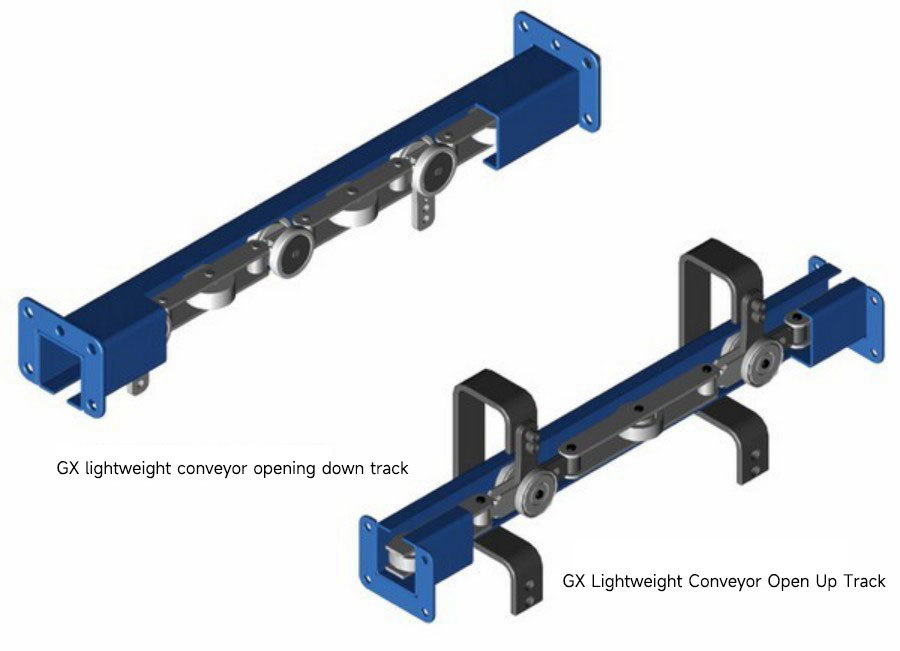

Track

The track of this series of conveyors adopts the form of an open rectangle. In practical applications, the track opening can be upward or downward. The upward opening of the track can avoid contamination of the workpiece by the conveying system during the conveying process.

| GX series light conveyor horizontal and vertical curved rail technical parameters | ||||||

| Model | Parameters | |||||

| Rail size | Maximum lifting weight per meter | Horizontal curved rail | Vertical curved rail | |||

| Turning radius mm | Turning angle ° | Turning radius mm | Turning angle ° | |||

| GX150-35 | 65×68×4 | 110Kg | 600/800 | 15/30/45/90/180 | 1000/1500 | 15/30/45 |

| GX180-35 | 65×68×4 | 110Kg | 600/800 | 15/30/45/90/180 | 1000/1500 | 15/30/45 |

| GX200-35 | 65×68×4 | 110Kg | 600/800 | 15/30/45/90/180 | 1000/1500 | 15/30/45 |

| GX250-35 | 65×68×4 | 110Kg | 600/800 | 15/30/45/90/180 | 1000/1500 | 15/30/45 |

| GX270-35 | 65×68×4 | 110Kg | 600/800 | 15/30/45/90/180 | 1250/1500 | 15/30/45 |

| GX300-35 | 65×68×4 | 110Kg | 600/800 | 15/30/45/90/180 | 1250/1500 | 15/30/45 |

| GX 250-50 | 75×80×4 | 150Kg | 600/800 | 15/30/45/90/180 | 1250/1800 | 15/30/45 |

| GX270-50 | 75×80×4 | 150Kg | 600/800 | 15/30/45/90/180 | 1250/1800 | 15/30/45 |

| GX300-50 | 75×80×4 | 150Kg | 1000/1500 | 15/30/45/90/180 | 1250/1800 | 15/30/45 |

| GX400-50 | 75×80×4 | 150Kg | 1000/1500 | 15/30/45/90/180 | 1250/1800 | 15/30/45 |

| GX300-100 | 80×100×4 | 200Kg | 600/800 | 15/30/45/90/180 | 1250/1500 | 15/30/45 |

| GX400-100 | 80×100×4 | 200Kg | 600/800 | 15/30/45/90/180 | 1250/1500 | 15/30/45 |

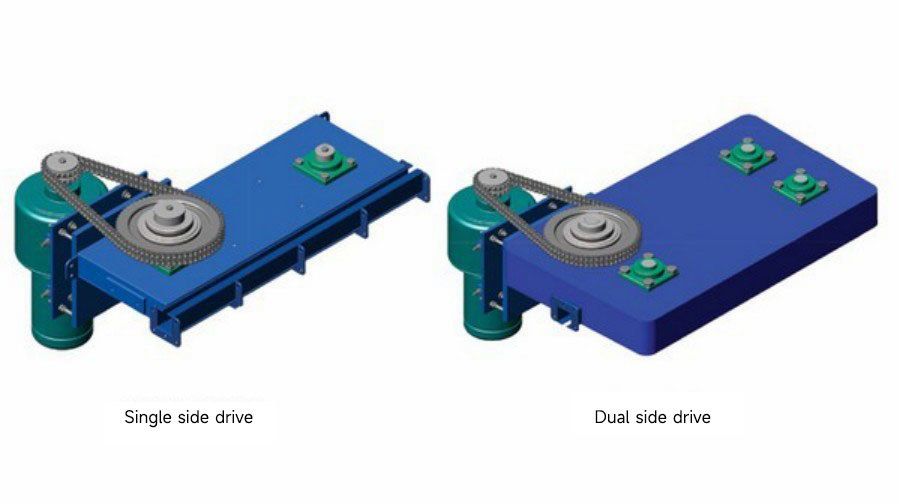

Drive device

There are two types of drive devices, one is single-side drive and the other is double-side drive. Both types of drives are linear crawler drives, which can achieve stepless speed regulation. The maximum traction force is: 400Kg for single-side drive and 500Kg for double-side drive. The speed of both drives is adjustable within the range of 0-15m/Min, and a torque limiter type overload protection device is provided. Both drive devices have the advantages of stable operation and high positioning accuracy of stepping operation.

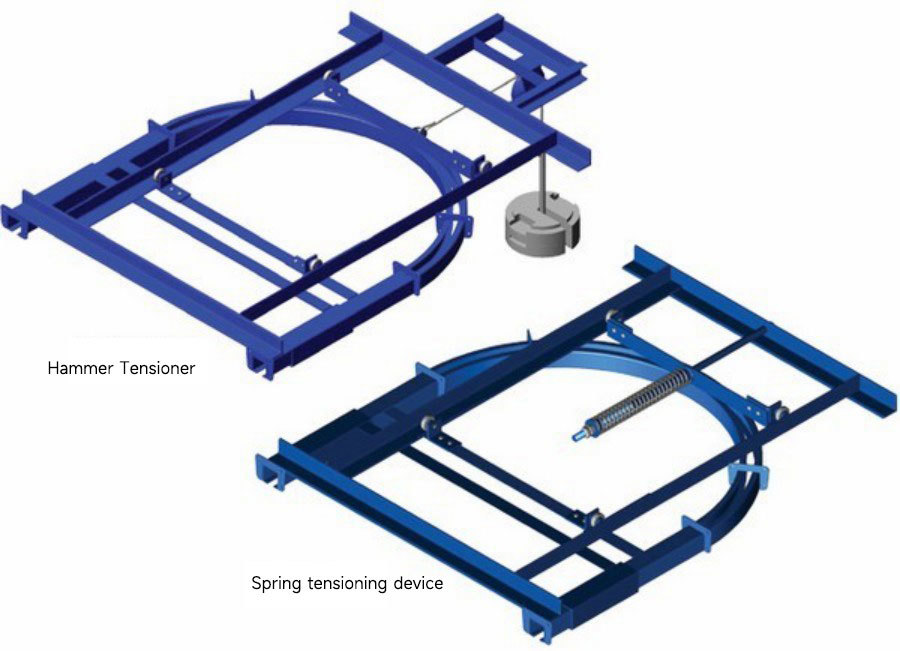

Tensioning device

There are generally two types of tensioning devices, spring tensioning and weight tensioning. Spring tensioning is generally used for conveying lines with short conveying lines and low working temperatures. Weight tensioning is used for conveying lines with long lines, many ups and downs, and high and fluctuating working temperatures.

Application

GET A FREE QUOTE