JXW Series Accumulation Conveyor

Category:

Power and Free Conveyor

Chat with us now for a quick response.

Chat with us now for a quick response.

Keyword:

JXW Series Accumulation Conveyor

With its reliable load control capability, the accumulation conveyor is very suitable for various production, assembly and conveyor lines where the production process between various stations on the entire production line needs to be coordinated. The accumulation conveyor can stop or run the load separately without interfering with each other when the entire production line is running normally. The conveyed load can be stored online, and longer loads can be stored obliquely in dense storage areas to save space. The use of an integral wide push rod and lifting claw can evenly distribute the tension of the chain to the push rod and the push rod outer connecting piece, so that its stress is minimized, which not only makes the load-bearing vehicle group run quickly and smoothly, but also improves its service life. The load-bearing track is made of high-carbon alloy manganese steel, which improves the load-bearing capacity and safety of the conveyor.

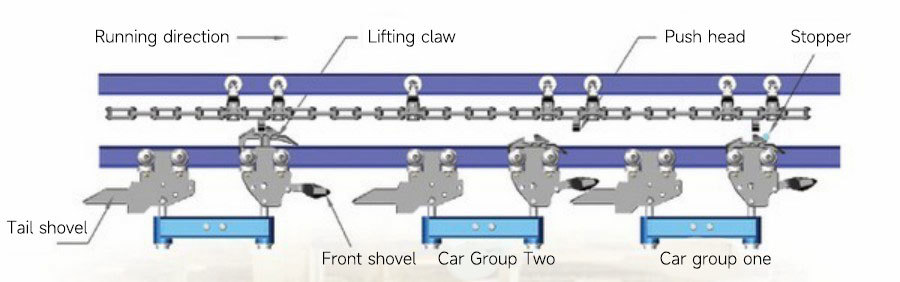

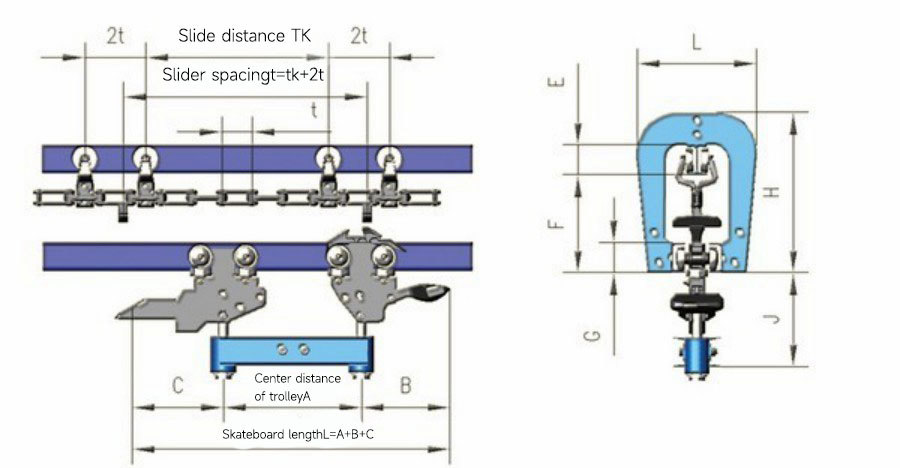

The accumulation conveyor is generally composed of a power system, a traction straight rail, a traction curved rail, a load-bearing straight rail, a load-bearing curved rail, a load-bearing vehicle group, a merging turnout, a branch turnout, a stopper and an electronic control system. The accumulation principle The accumulation vehicle group generally consists of a front trolley, a rear trolley and a load beam. A front shovel is installed on the front car and connected to the lifting claw through a connecting mechanism, and a tail shovel is installed on the rear car. When the accumulation operation is required, the pneumatic stopper is opened, and the lifting claw on the front car of the No. 1 group is pressed down to disengage it from the push head on the traction chain, and the No. 1 group stops running. The No. 2 group continues to move forward until the front shovel of the front car rises along the inclined surface of the tail shovel of the rear car of the No. 1 group, driving the lifting claw down and disengaging it from the traction chain, and the No. 2 group stops running, and the subsequent groups are similar. When the accumulation operation is completed, the pneumatic stopper is closed, and the lifting claw on the front car of the No. 1 group is lifted by the weight of the front shovel itself, and the push head on the traction chain is in place to push the No. 1 group forward. As the No. 1 group moves forward, the front shovel of the front car of the No. 2 group is disengaged from the tail shovel of the rear car of the No. 1 group, and the lifting claw is lifted to complete the accumulation operation.

JXW series accumulation conveyor is a product developed by our company by fully absorbing the design and manufacturing technology of ASI Automation Systems of the United States and combining it with the national conditions of my country. This series is divided into three varieties according to the load-bearing capacity of the trolley, namely 3″, 4″ and 6″. This series of accumulation conveyor can complete the functions of automatic transportation, storage, sorting and delivery of materials, realize the automation of complex production processes, and more effectively organize fast-paced and efficient modern large-scale production.

This series of accumulation conveyors adopts a new wide push rod, the working surface of which is three times wider than that of the original drag chain push rod, making the conveyor run more smoothly and reliably. The wide push rod is equipped with a pressure block, which fundamentally improves the transfer method of the accumulation trolley, simplifies the original two transfers to one transfer, shortens the transfer time, speeds up the production cycle, and effectively improves the reliability of turnout transfer.

| Technical parameters of JXW series stacking conveyor chain and car group | |||||||||||

| Model | Parameters | ||||||||||

| t | A | B | C | D | E | F | G | H | J | L | |

| JXW3 | 3″ | Optional | 229 | 80 | 125 | 80 | 243 | 80 | 400 | 340 | Optional |

| JXW4 | 4″ | Optional | 290 | 123 | 144 | 100 | 273 | 100 | 441 | 375 | Optional |

| JXW6 | 6″ | Optional | 298 | 118 | 245 | 100 | 386 | 160 | 615 | 380 | Optional |

Application

GET A FREE QUOTE