XT Series Light Conveyor

Category:

Light Duty Overhead Conveyor

Chat with us now for a quick response.

Chat with us now for a quick response.

Keyword:

XT Series Light Conveyor

| XT Series Lightweight Conveyor Technical Parameters | ||||||

| Model | Parameters | |||||

| Chain pitch t | Allowable chain tension | Conveyor speed | Single point lifting weight | Working temperature | Deadweight | |

| XT150.8 | 150 | 2.5KN | 15m/min | 8Kg | -20~280℃ | 2.8Kg/m |

| XT200.32 | 200 | 5KN | 15m/min | 32 Kg | -20~280℃ | 5.5 Kg/m |

| XT250.32 | 250 | 5KN | 15m/min | 32 Kg | -20~280℃ | 4.7 Kg/m |

| XT300.32 | 300 | 5KN | 15m/min | 32 Kg | -20~280℃ | 4.5 Kg/m |

| XT200.50 | 200 | 5KN | 15m/min | 50 Kg | -20~280℃ | 7.8 Kg/m |

| XT250.50 | 250 | 5KN | 15m/min | 50 Kg | -20~280℃ | 7.4 Kg/m |

| XT300.50 | 300 | 5KN | 15m/min | 50 Kg | -20~280℃ | 7.0 Kg/m |

| XT300.100 | 300 | 7KN | 15m/min | 100 Kg | -20~280℃ | 11 Kg/m |

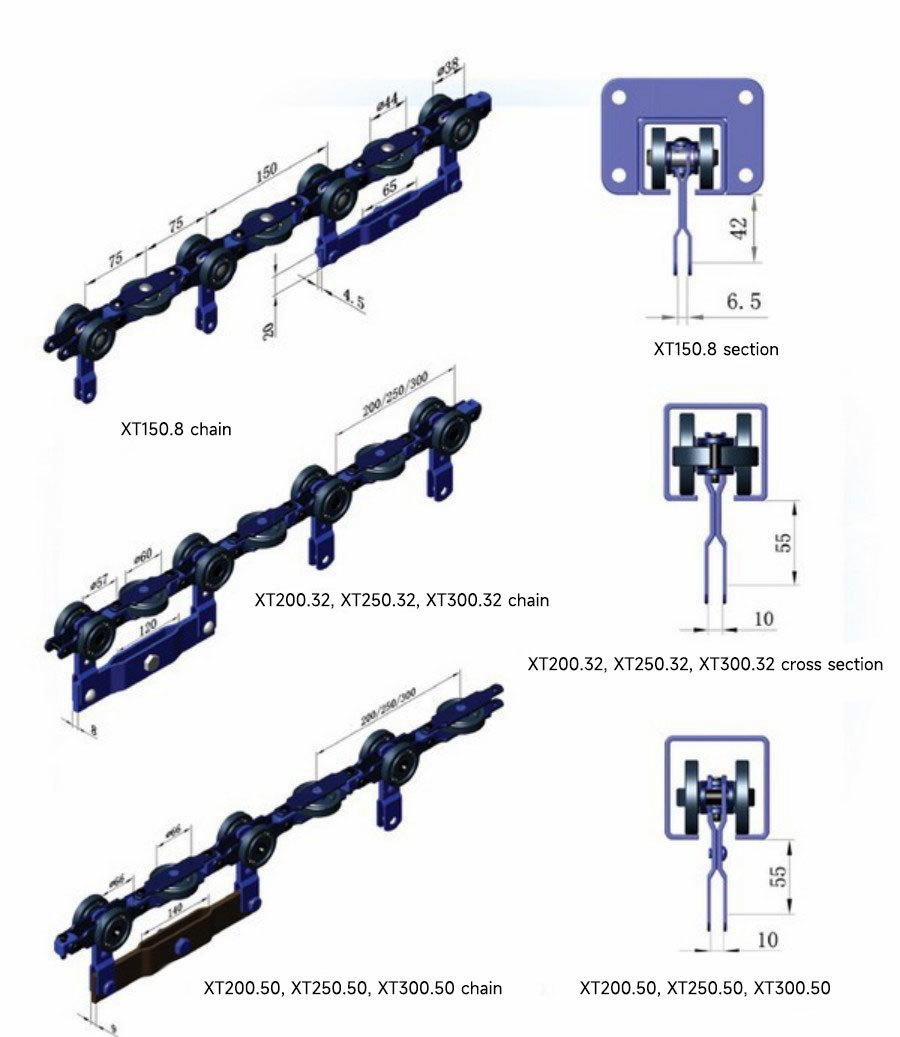

Chain Types

According to the different load weights, chains are divided into many different models, and the single-point lifting weight ranges from 8Kg to 100Kg. Users can choose the corresponding chain model according to the specific weight of the workpiece to be transported and the working environment. The chain consists of chain plates, running wheels, guide wheels, intermediate sections, etc.

The chain plates are made of 50Mn steel, and the running wheels and guide wheels all use integral bearing wheels. The running wheels and guide wheels are set alternately, so that the horizontal and vertical bending performance of the chain is very excellent, and the running resistance is reduced to a minimum. The chain is connected to the workpiece to be transported through the hanger installed on the running wheel shaft. The spacing of the hanging workpiece depends on the specific requirements of the user, but the hanging spacing can only be an integer multiple of the chain pitch. The workpiece can be hung at a single point or a double-point composite hanging. The weight of the composite hanging workpiece is twice the weight of the single-point hanging.

Chain size

Track and track connection

The track is made of open square steel pipe, which has the characteristics of beautiful appearance and no exposed moving parts. In addition to improving the dust and dirt resistance of the chain itself, it also reduces the faults such as touching and scratching the chain caused by accidental events, and enhances safety.

There are two ways to connect the track. One is the bracket connection, which uses four bolts to fasten the connection between the tracks to be connected. The other is to clamp and weld with special tools at the connection between the two tracks.

The track is divided into standard straight track, horizontal curved track, vertical (upward arch, downward deflection) curved track, thermal telescopic track and inspection track according to its function.

1. Standard straight track

The standard straight track of the light conveyor is composed of an open square steel pipe and a bracket. The length of the standard straight track is 6000mm, and connecting brackets are installed at both ends. In order to strengthen the strength of the track, a bracket is sometimes installed in the middle.

2. Horizontal curved track

| Technical parameters of horizontal and vertical curved rails of XT series light conveyor | ||||||

| Model | Parameters | |||||

| Rail dimensions | Maximum lifting weight at single point | Horizontal curved rail | Vertical curved track | |||

| Turning radius mm | Turning angle ° | Turning radius mm | Turning angle ° | |||

| XT150.8 | 54×47 | 8Kg | 500/600 | 30/45/90/180 | 500/600 | 15/30/45 |

| XT200.32 | 72×68 | 32 Kg | 600/800/1000 | 30/45/90/180 | 600/800/1000< /td> | 15/30/45 |

| XT200.50 | 80×80 | 50 Kg | 600/800/1000 | 30/45/90/180 | 600/800/1000< /td> | 15/30/45 |

| XT250.32 | 72×68 | 32 Kg | 600/800/1000 | 30/45/90/180 | 600/800/1000< /td> | 15/30/45 |

| XT250.50 | 80×80 | 50 Kg | 600/800/1000 | 30/45/90/180 | 600/800/1000< /td> | 15/30/45 |

| XT300.32 | 72×68 | 32 Kg | 600/800/1000 | 30/45/90/180 | 600/800/1000< /td> | 15/30/45 |

| XT300.50 | 80×80 | 50 Kg | 600/800/1000 | 30/45/90/180 | 600/800/1000 | 15/30/45 |

| XT300.100 | 80×100 | 100 Kg | 600/800/1000 | 30/45/90/180 | 600/800/1000 | 15/30/45 |

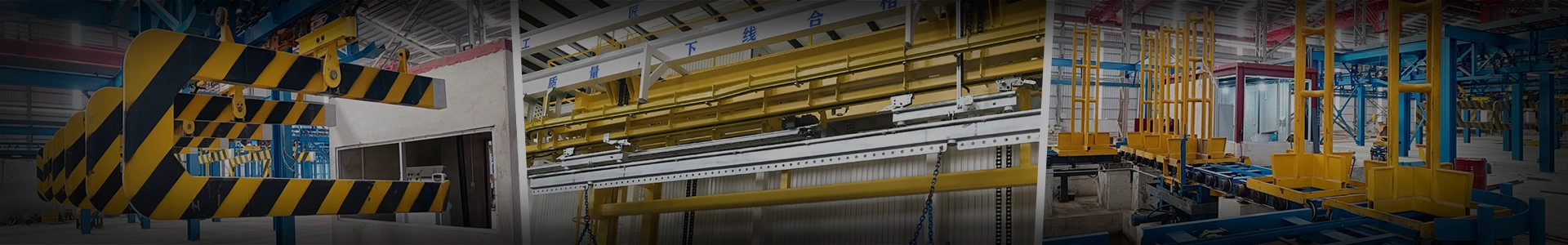

Application

GET A FREE QUOTE