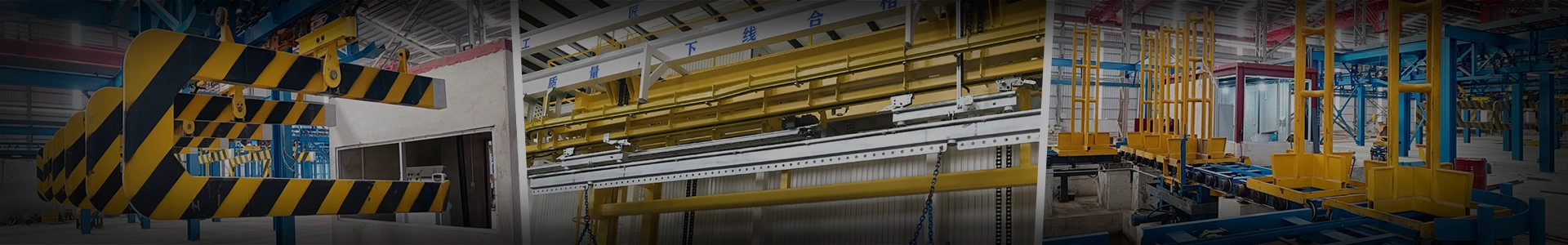

XT Series Heavy Duty Conveyor

Category:

Heavy Duty Overhead Conveyor

Chat with us now for a quick response.

Chat with us now for a quick response.

Keyword:

XT Series Heavy Duty Conveyor

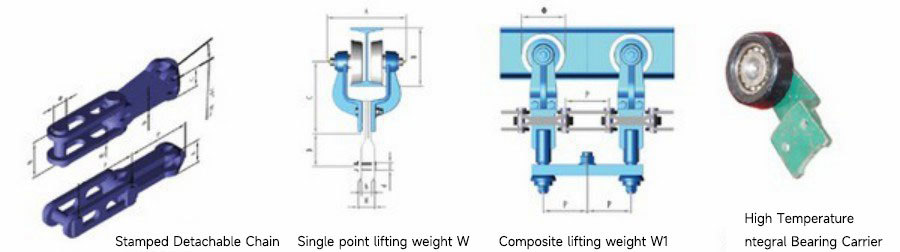

In addition to 3″, 4″, and 6″ pitch universal conveyors, there are also three types of general conveyors: XT80, XT100, and XT160. This type of conveyor uses stamped detachable chains or die-forged chains, with simple structures, safe operation, and good stability. To adapt to various working conditions, there are two types of slides, one is a common slide and the other is a high-temperature integral bearing slide.

Drive device

The drive device is the power source of the conveyor. There are two types of drives for heavy conveyors, one is the angular drive device and the other is the linear drive device. The angular drive device has the advantages of simple structure and low cost, but the disadvantage is that it can only be installed

At the horizontal turning point of the traction chain, the conveyor line layout is limited. The safety pin is used for safety protection. It is generally used in conveying systems with simple lines; the linear drive device is widely used in any linear chain drive. It consists of a sleeve roller transmission chain and a pusher. With the help of the mutual meshing of the drive pusher and the detachable chain, it moves forward to ensure the normal operation of the conveyor. The overload protection is that a supporting cantilever is installed on the reducer, and the other end of the cantilever is connected to the drive frame. The cantilever is equipped with an overload protection spring. Under normal conditions, the driving force is just balanced with the counter torque formed by the spring. When the resistance in the line is large, the driving torque increases accordingly, the reducer body rotates, and the spring is further compressed. When the driving force reaches 1.5 times the rated tension, the travel switch is triggered and the car stops.

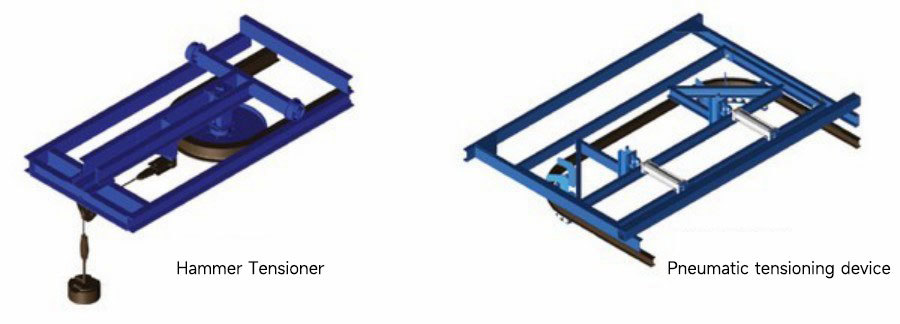

Tensioning device

The tensioning device structure adopts heavy hammer or pneumatic tensioning, light wheel or roller array rotation, and the tensioning working stroke can reach 700 mm, which can ensure that the initial tension of the chain remains unchanged, the operation is reliable, and the conveyor can work safely in any working environment.

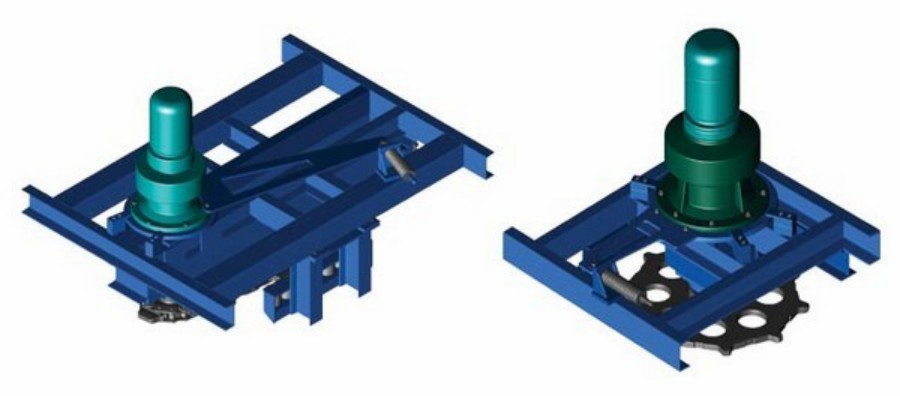

Slewing device

The function of the slewing device is to make the conveyor turn horizontally, which can be divided into two types: light wheel rotation and roller array rotation

Application

GET A FREE QUOTE