GFJ series reverse accumulation conveyor

Category:

Floor Conveyor

Chat with us now for a quick response.

Chat with us now for a quick response.

Keyword:

GFJ series reverse accumulation conveyor

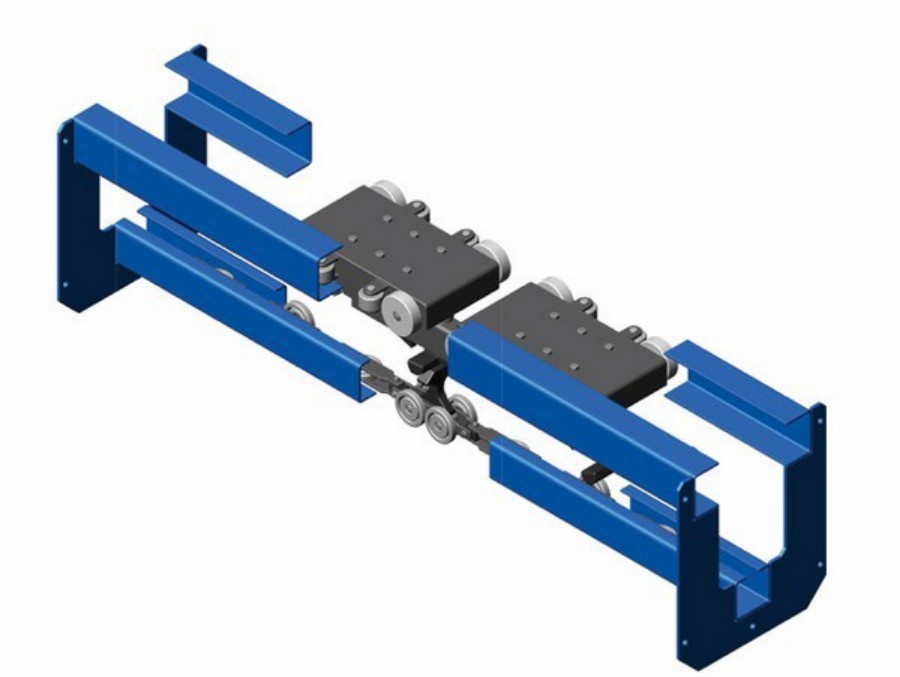

GFJ100 reverse accumulation conveyor system is a new product developed by Everbright Company. It has the advantages of stable operation and accurate positioning of skid conveyor, and the flexibility of ordinary reverse accumulation conveyor. It can complete the functions of conveying, storing, sorting and transferring workpieces. Since the workpieces are mounted on the trolley, track, lubricating oil and dirt on the traction chain and process bracket will not fall on the moving workpiece, thus minimizing the pollution of the workpiece. At the same time, the operator is not affected or interfered by the sling when working, which is suitable for robot operation and is an ideal conveying equipment for the coating industry.

Technical features:

GFJ100 ground conveyor, including double-layer tracks, the lower traction track is used for running chains, and the upper one is a load-bearing track for running the load-bearing trolley. The front and rear of the load-bearing trolley are equipped with push claws, which move forward through the push head installed on the traction chain. The trolley is made of steel plate and equipped with process trays. The travel and guidance are achieved by 4 load-bearing wheels and 4 guide wheels respectively. The push head distance and accumulation distance on the traction chain are designed according to user requirements. Each trolley or car group can be separated from the traction chain to achieve accumulation. When the trolley encounters a stopper or the tail of the previous trolley, the accumulation rod is lowered and the trolley push claw is raised to achieve accumulation. The conveyor can achieve changes in vertical height through uphill and downhill sections.

Technical parameters:

| Chain pitch | 180/270/300mm |

| Chain maximum thrust | 400Kg |

| Maximum ambient temperature | 250℃ |

| Standard running accuracy | ±2mm |

| Carrying capacity | 100Kg (single car)/200Kg (double car) |

| Trolley bearing | closed grease lubrication, maintenance-free |

| Horizontal curved rail | |

| Angle | 90°/45°/30°/15° |

| Radius | 700/1000/1500mm |

| Vertical curved rail | |

| Angle | 30°/15° |

| Radius | 700/1500/2000mm |

| Note | Special dimensions can be designed as required |

| Car group | front and rear car accumulation |

| Switch switch | pneumatic R=700mm |

| Drive device | linear drive (speed adjustable) |

| Tensioning device | heavy hammer or pneumatic tensioning |

| Stop | pneumatic |

| Lubrication | multi-way automatic lubrication |

Application

GET A FREE QUOTE