CXT160 Heavy-duty Conveyor

Category:

Heavy Duty Overhead Conveyor

Chat with us now for a quick response.

Chat with us now for a quick response.

Keyword:

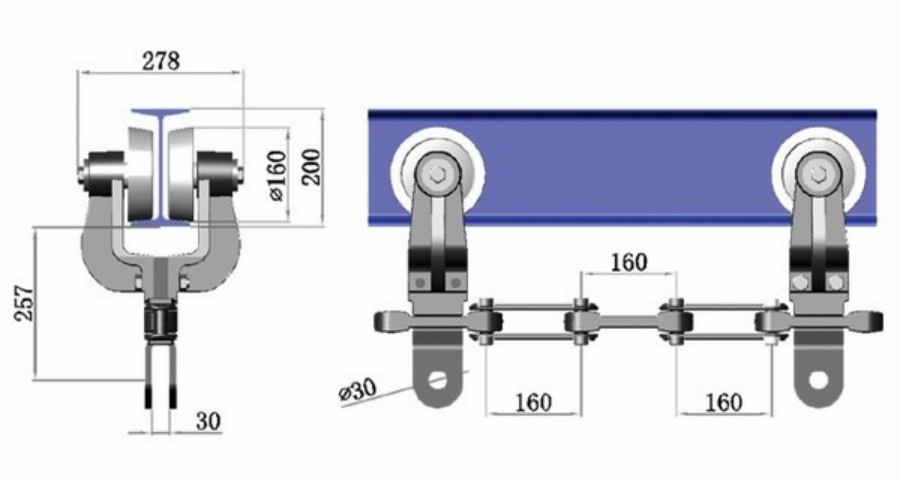

CXT160 Heavy-duty Conveyor

The CXT160-1000 universal suspension conveyor is a newly developed super-heavy universal suspension conveyor based on the original XT160 suspension conveyor's operating principle and application status, after years of market research, technical demonstration and data theoretical calculation of key components by our company's marketing and professional technical personnel. The outstanding feature of this product is that it can adapt to the mechanized transportation of oversized objects, filling the gap in the field of heavy-duty conveyors in China.

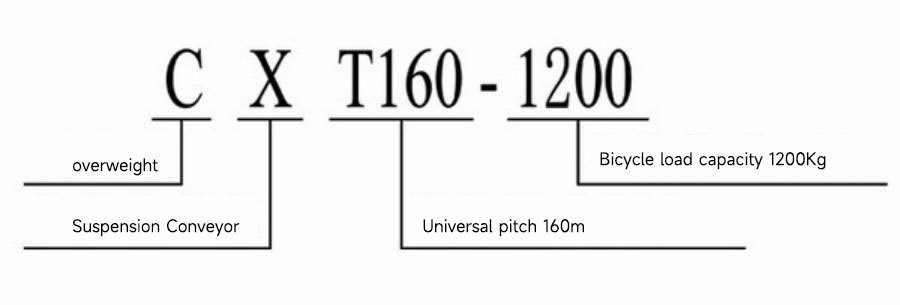

Product model and meaning

Technical parameters

1. Single point lifting weight: 1200Kg (including secondary lifting device)

2. Track: 20 (material A3)

3. Traction chain pitch: t=160mm

4. Minimum hanging distance: 640 (20 tracks)/960 (18 tracks)

5. Allowable tension of traction chain: 2700Kg

6. Diameter of carriage roller: φ160mm

7. Heat treatment hardness of carriage roller tread: HRC30°

8. Running speed: 0.3~10m/Min (optional)

9. Horizontal rotation of light wheel: radius 600\800\1000 angle 90°\180°

10. Horizontal rotation of roller group: radius 90012001500\2000 Angle 15°30°\45°\90°\180°

11. Vertical climbing curved track section: R4800 for 4t, R6000 for 6t

Composition and application of conveying system

1. Transmission device: linear crawler drive, different types of motors and reducers can be configured according to driving force and running speed, and equipped with overload torque limiter to achieve overload protection.

2. Tensioning device: according to the process conditions and the size of the turning radius, two types of heavy hammer or pneumatic tensioning devices can be configured, namely, light wheel or roller group.

3. Track: can be respectively used, domestic profile I-beam of 18 or 20, and the curved track manufacturing process adopts cold bending one-time forming.

4. Traction chain: high-quality alloy die-forged detachable chain.

5. Slide: divided into load slide, heavy load slide, support empty slide, its structural slide body is forgeable cast iron, and the roller is a special large clearance integral bearing wheel. Lubrication can be done by grease or automatic spray of thin oil. When the carriage passes through the high temperature zone, high temperature resistant grease needs to be added to prevent the grease from carbonizing under high temperature, causing the roller to get stuck and increase the running resistance. According to the hoisting load, load carriage hanging or heavy load carriage hanging can be used respectively.

6. Rotation device: According to the working conditions, line tension and the size of the rotation radius, the light wheel rotation device or the roller group rotation device can be used respectively.

7. Temperature telescopic rail: When the conveyor passes through the high temperature zone (80~200°), due to the change of ambient temperature, the track expands and extends. Under this condition, the temperature telescopic rail must be configured to prevent the high temperature equipment from being pulled and deformed or the weld cracking.

8. Lubrication device: It is used for chain lubrication, reducing wear, preventing rust, making the operation of the whole system light and flexible, and extending the service life of the conveying system. It is recommended to use the WR-100 multi-channel automatic lubrication device produced by our company.

Application

GET A FREE QUOTE